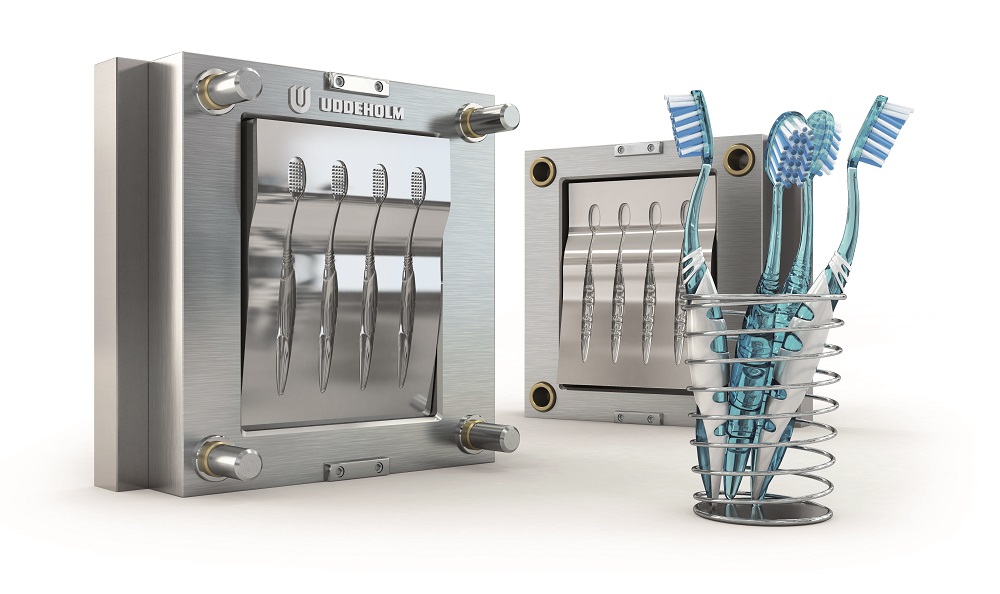

Plastic Moulding

Plastic Moulding is a part of our everyday lives. Car parts, mobile phones, spectacles, computer chassis are all manufactured by moulds. However the materials needed to make these moulds often require unique and demanding characteristics. This is why it is crucial to select the correct steel grade for your specific mould.

Many of the most well-known brands use Uddeholm tool steel in their manufacturing processes, since plastic moulding is a demanding and evolving industry. Harsh environments put steel under considerable stress. Corrosion, hight temperatures, temperature changes and wear are just few of the most common challenges that tool users have to contend with – to say nothing of the expected quality at the end product. The problems are well-known, choosing the right tool steel is the solution.

Uddeholm Stainless concept is our own system of metallurgically balanced stainless grades. Grades that have been specially developed and continually refined to meet the needs of the evolving plastic moulding industry.