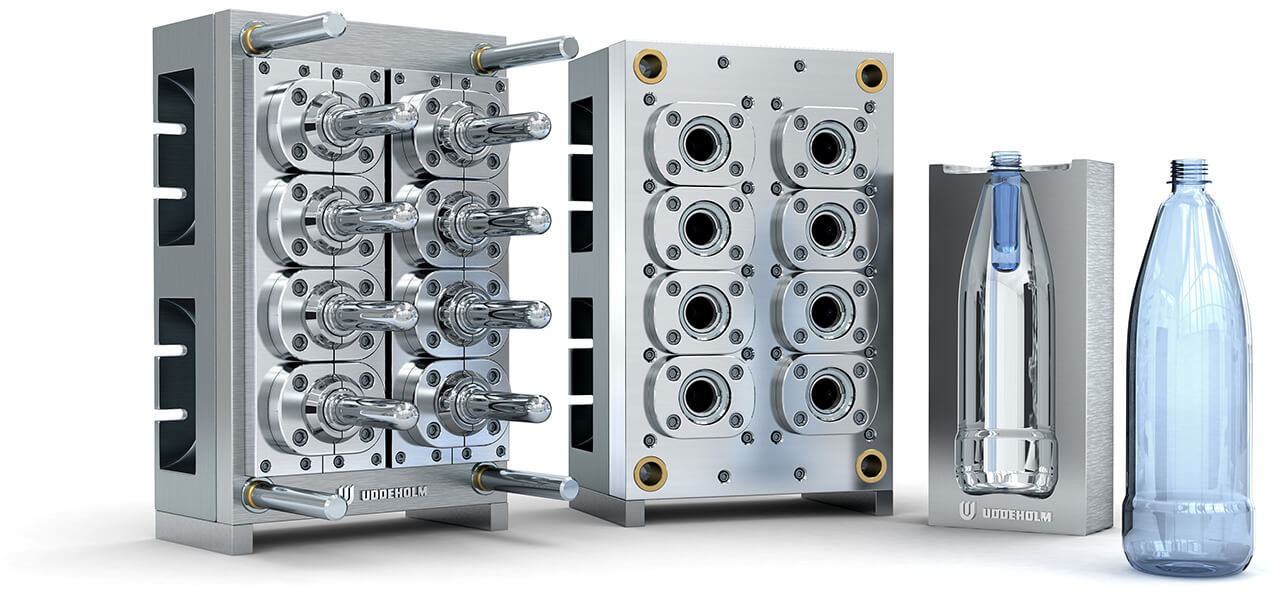

Blow moulding

Blow moulding is a process for shaping thermoplastic into a hollow product. A hot thermoplastic tube is stretched with air pressure and cooled against a mould surface.

Mould material requirements

Blow moulding is a low pressure method where strength and wear demands are very moderate. Some parts of the mould, like shot off areas and/or neck ring, may require higher strength material. PVC is a common material for bottles and may cause corrosion problems. Blow moulding is a very high productivity method why cycle times are of great importance. The most common material to use in blow moulds is aluminium alloys, with inserts of higher hardness materials. Steel is also used and in some cases even in the soft annealed condition.

Mould material properties

Important properties are:

- Moderate strength demands

- Corrosion resistance

- Heat conductivity