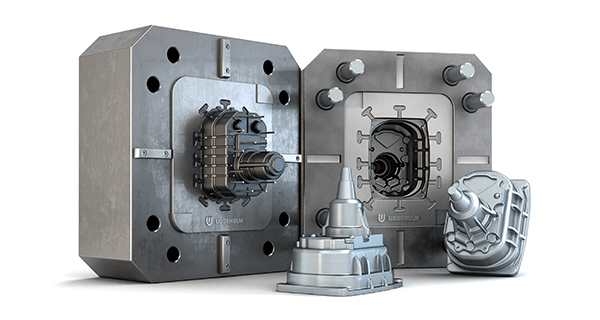

Hot Work Tool Steel

Hot work is one of the most challenging areas of manufacturing with constantly increasing demands on the die and tool steel. Most of the application areas share similar problems such as:

- Hot wear

- Thermal fatigue

- Cracking

- Plastic deformation

Part manufacturers are under pressure to reduce the cost of each part produced. At Uddeholm we can help to optimize performance of your tooling with the correct choice of tool steel to best solve your problems.