flow filter V

Nozzle filters are used to prevent contamination from the plastic melt causing blockages or interruptions to the injection process. These contaminates can cause damage to hot runner systems resulting in extended downtime and increased maintenance costs.

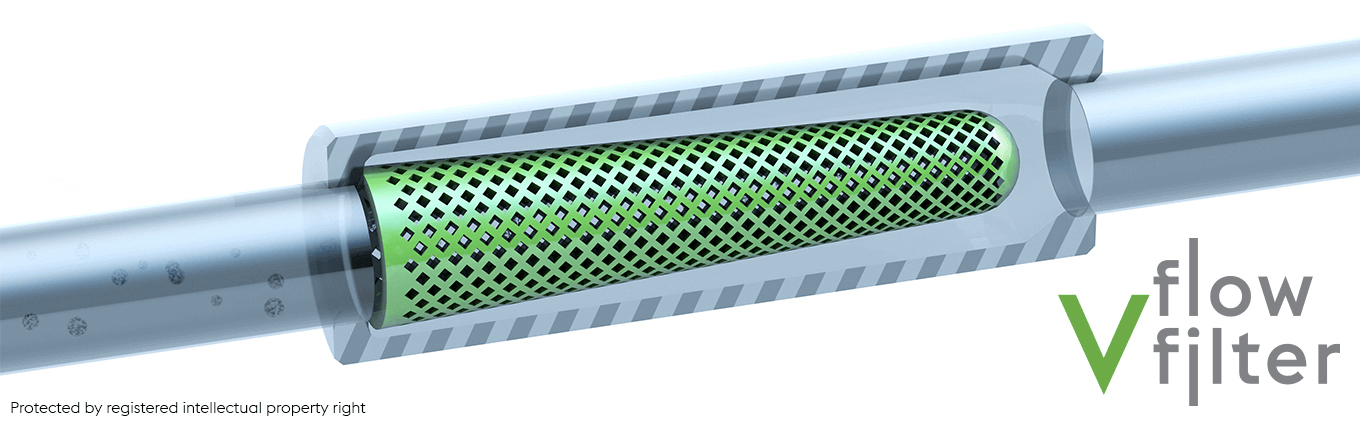

The design of the voestalpine flow filter V capitalizes on the unique capabilities of 3D printing to integrate a high density solid mesh filter into a standard form factor, delivering improved performance over traditional injection moulding nozzle filters.

This configuration of in-line filter helps prevent feed blockages caused by material impurities, such as those encountered when processing recycled materials while minimizing overall pressure drop.

CHARACTERISTICS

- Extremely low pressure drop

- Very low shear stress

- Small mesh size

- Very large filtration area

- Corrosion resistant

- Wear resistant

BENEFITS

- Trouble-free injection molding

- Minimal increase in injection pressure

- Lower energy consumption

- Lower maintenance and downtime costs

- Better part quality

- Easy cleaning

- Long lifetime

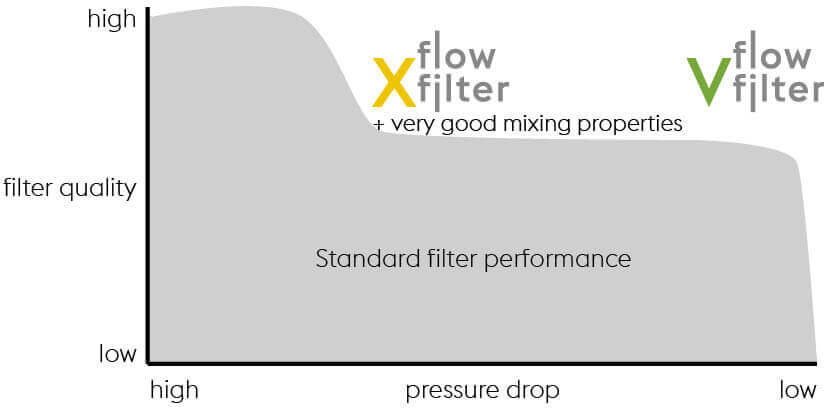

FEATURE COMPARISON

Pressure drop and shear stress can be influenced by many parameters (eg injection material, filler material, temperature, etc).

flow filter V should be selected for high quality filtration with minimum overall pressure drop.

voestalpine flow filters are not recommended for glass fiber reinforced plastics.

Special care should be taken when installing the flow filter V – please follow the instructions as per the “Mounting Information” datasheet.