Nozzle filters are used to prevent contamination from the plastic melt causing blockages or interruptions to the injection process. These contaminates can cause damage to hot runner systems resulting in extended downtime and increased maintenance costs.

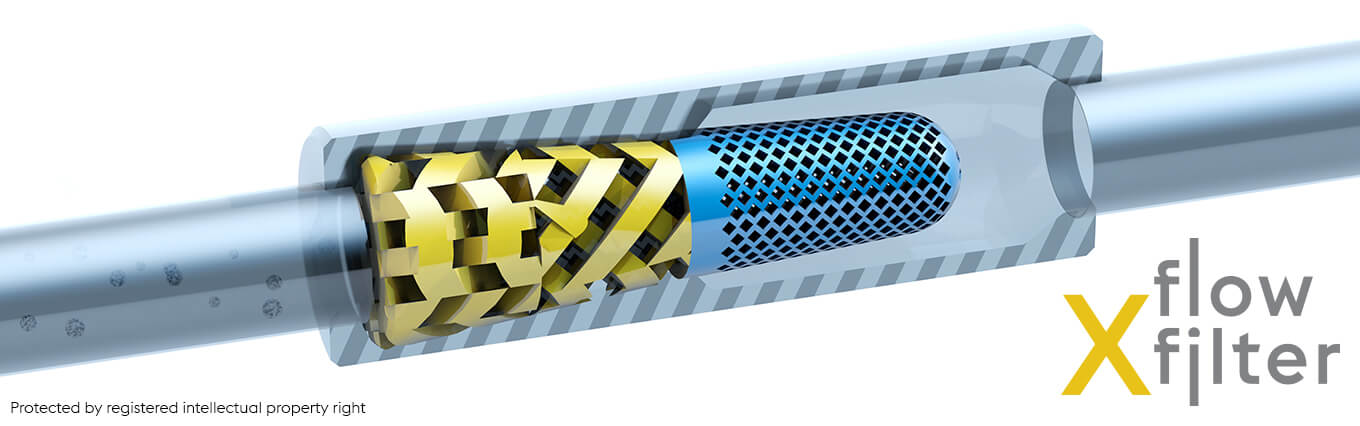

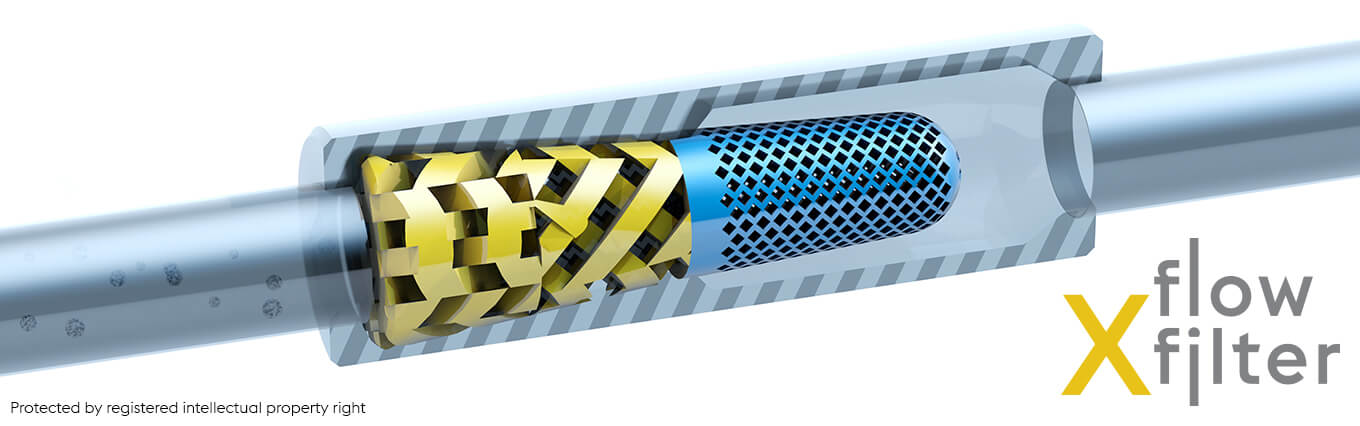

The design of the voestalpine flow filter X capitalizes on the unique capabilities of 3D printing to integrate a static mixer and filter into a standard form factor, delivering improved performance over traditional injection moulding nozzle filters.

This configuration of in-line static mixer and filter helps prevent feed blockages caused by material impurities, such as those encountered when processing recycled materials and delivers superior mixing properties when using additives.

Benefits

- Trouble-free injection moulding

- Lower maintenance and downtime costs

- Space-saving installation

- Better part quality

- Only slight increase in injection pressure

- Easy cleaning

- Long lifetime

Read more