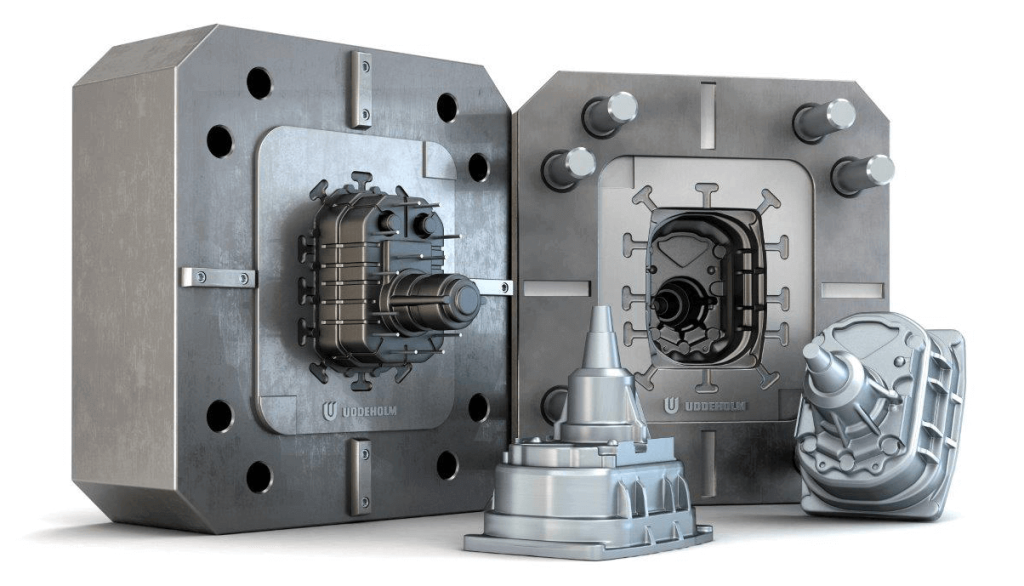

Die Casting

Pressure Die Casting offers an economical way of producing large quantities of complex, high tolerance parts in aluminium, magnesium, zinc and copper alloys. The material has to withstand both pressure and high temperatures.

In recent years, Uddeholm has played a leading role in developing hot work steel to meet the stricter demands of the die casting sector. Long production series are common and place tough demands on tools and materials. The increasing challenges in die cast products will ensure continued development of die casting alloys with higher strength and ductility, improved machinability, weldability and corrosion resistance.

We mainly produce clamping and holding plates as well as pre-machined inserts, and we have extensive experience of producing components that really do their job. Selecting material is an important part of the process. Uddeholm has the best knowledge about the best steels on the market – our own steel grades. This is a major benefit in terms of achieving truly excellent results.