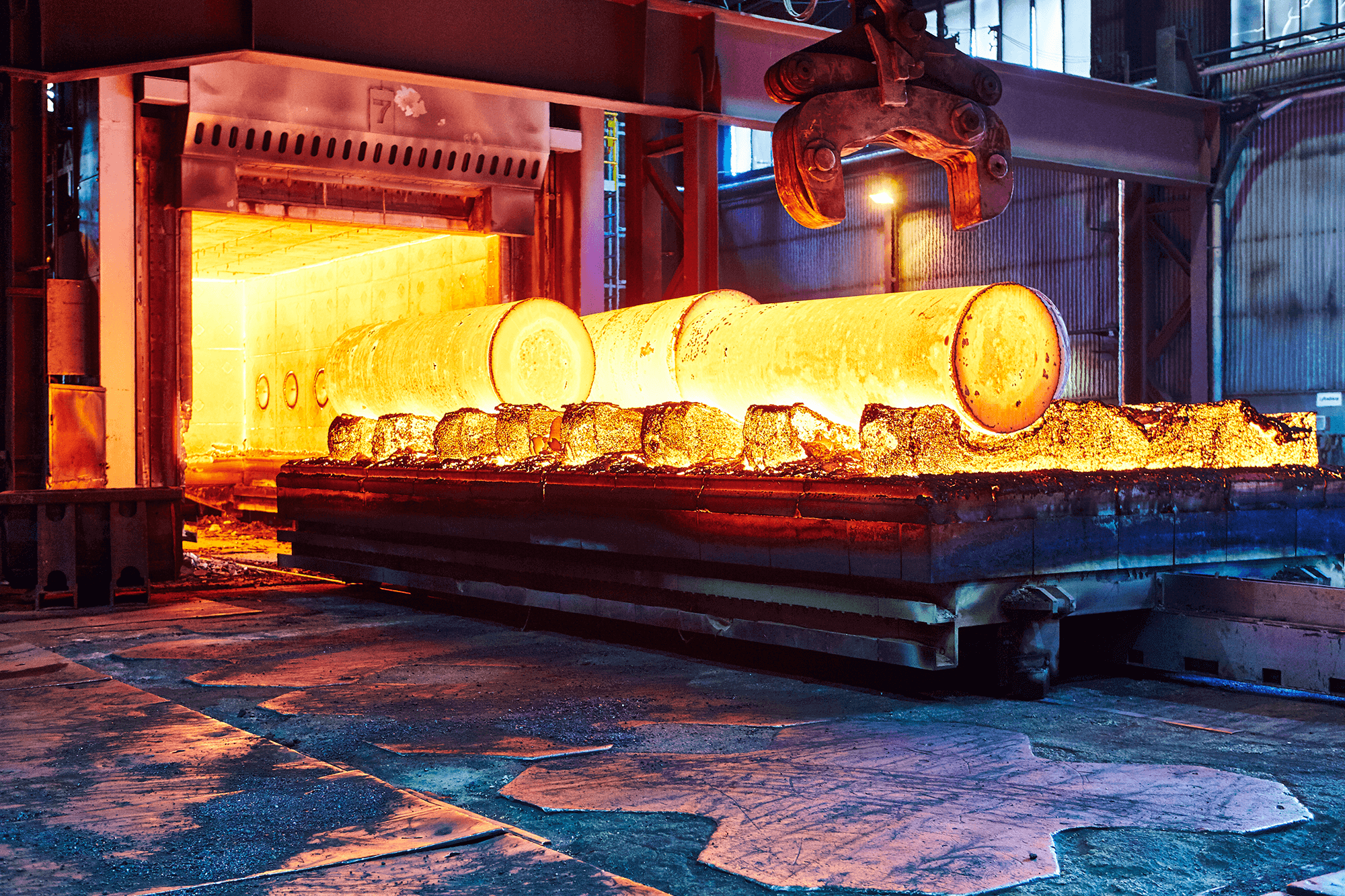

Heat treatment for better tool performance

High quality heat treatment is necessity to achieve full potential of the tooling material. It improves resistance against common failure mechanisms and increases overall performance. For your benefit, we are committed to supporting you with the most appropriate service.

Our tool steels are normally delivered in the soft annealed condition, to make it easier for tool makers to machine. The tool steel can then easily be heat treated according to the tool user’s specific needs. Uddeholm can support you with heat treatment services such as soft annealing, stress relieving, hardening and tempering.

The services are provided in our own facilities or through exclusive partners. Our service offer may differ between markets.