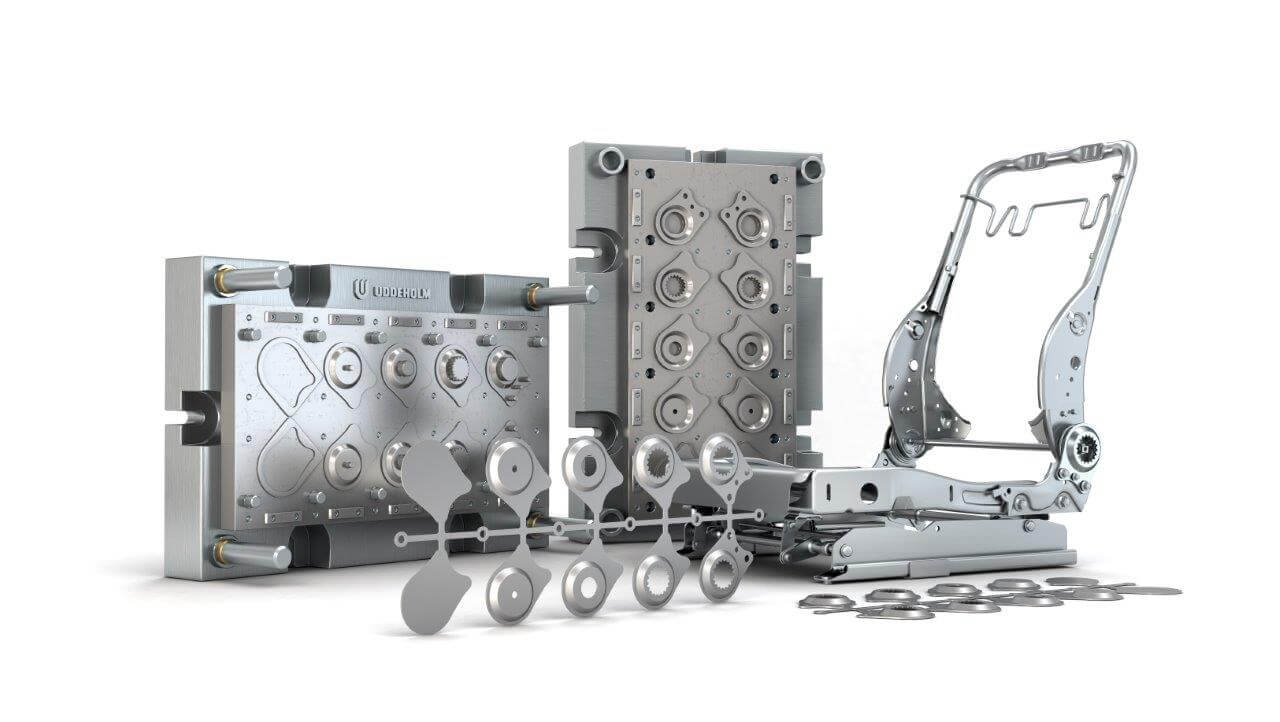

Cold Work Applications

When it comes to cold work, any tool steel fit for the job needs to be sturdy. Common failure mechanisms are wear galling, chipping and cracking. As in any other tool steel application, optimal tooling economy – the lowest cost per produced part – can only be achieved by choosing the right tool steel for the job.

The performance of a tool steel is often measured by the quality of the parts it produces. While it is true that higher quality tool steel leads to better results, it is also wise to consider other aspects of tool production, such as machinability and surface treatment. Uddeholm offers a selection of cold work tool steel engineered to counter any failure mechanism that may arise when performing heavy-duty cold work, such as cold forming, blanking and coining.

The cleaner the steel, the better the results. Uddeholm’s electro slag remelted (ESR) and powder metallurgy (PM) steel grades are among the purest on the market and will give you unparallelled results in terms of tool performance, tool life and predictability.

ALL TOOL STEEL FOR COLD WORK APPLICATIONS

- Uddeholm Arne

- Uddeholm Caldie

- Uddeholm Calmax

- Uddeholm Carmo

- Uddeholm Corrax

- Uddeholm Dievar

- Uddeholm Elmax SuperClean

- Uddeholm Formax

- Uddeholm Impax Supreme

- Uddeholm Mirrax 40

- Uddeholm Mirrax ESR

- Uddeholm Nimax

- Uddeholm Nimax ESR

- Uddeholm Orvar 2 Microdized

- Uddeholm Orvar Supreme

- Uddeholm QRO 90 Supreme

- Uddeholm Rigor

- Uddeholm Rigor

- Uddeholm RoyAlloy

- Uddeholm Sleipner

- Uddeholm Sverker 21

- Uddeholm Sverker 3

- Uddeholm Tyrax ESR

- Uddeholm UHB 11

- Uddeholm Unimax

- Uddeholm Unimax

- Uddeholm Vanadis 23 SuperClean

- Uddeholm Vanadis 23 SuperClean

- Uddeholm Vanadis 30 SuperClean

- Uddeholm Vanadis 4 Extra SuperClean

- Uddeholm Vanadis 4 Extra SuperClean

- Uddeholm Vanadis 60 SuperClean

- Uddeholm Vanadis 8 SuperClean

- Uddeholm Vanadis 8 XL

- Uddeholm Vanax SuperClean

- Uddeholm Vancron SuperClean

- Uddeholm Vidar 1 ESR

- Uddeholm Viking